Introduction

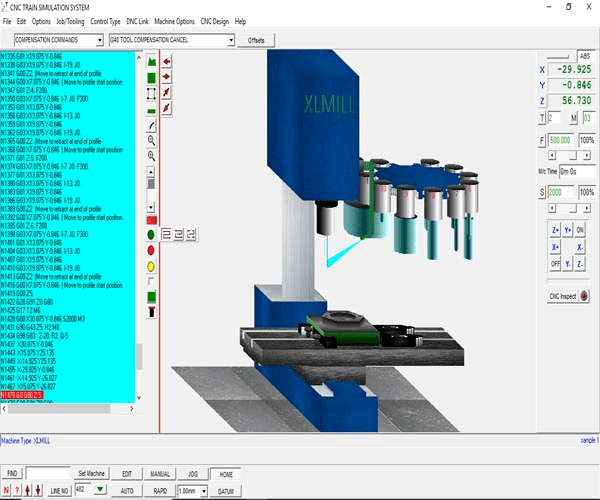

If you ever come across digital manufacturing programming and simulation software, You've probably heard of CNC training software. It is helpful to simulate machine operations before production to counter any issues that may arise, both with traditional machining tools and newer additive manufacturing machines like 3D printers. This is where CNCTrain simulation software for computer numerical control (CNC) comes in. CNC stands for Computer Numerical Control, and it is a method of automating and controlling the movement of manufacturing machines.

CNCTrain simulation tool is mathematical programs that predict the behaviour, performance, and outcome of manufacturing processes. CNCTrain enable the CNC programs, which is normally written in G-code, we test and verify g-code before sending to the machine.

Here,I will briefly explain to you this software.

About CNCTrain

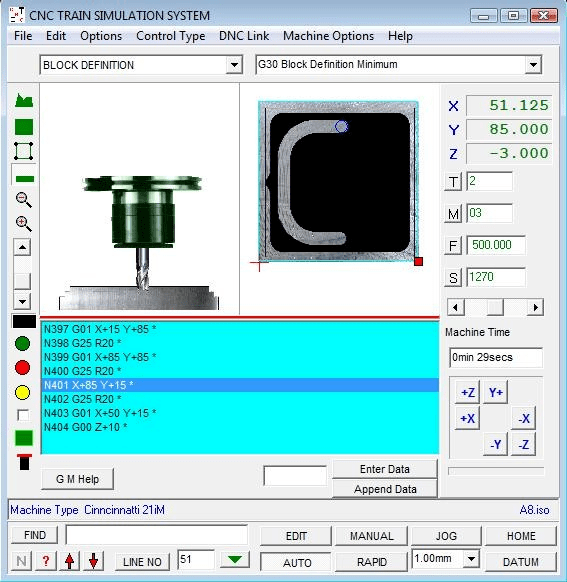

It is a two-axis CNC Lathe and three-axis CNC Mill programming and simulation software system that includes setup and MDI programming. Multiple management programming options are available for CNCTrain. You can enter a program code using the Window editor in CNCTrain software, which also offers features like On-Screen administration, MDI hardware, and the capacity to generate CAM code using the built-in CAM module. When using different screen resolutions or when the CNC lines are long, this program can be useful. You can also move the CNC editor to the left or right side of the window.

CNCTrain includes the following modules:

CNCWizard-A wizard helps you through the creation of your part program. A built-in library for machining processes is paired with reference material and illustrations to assist you throughout the programming of your part.

- CNCWrite-CNC writing machine is an automatic writing machine that can write any type of text and draw any style on paper. To handle a CNC writing machine, three-axes is essential(x-axis, y-axis, and z-axis). The x-axis and y-axis work together to make a 2D image on plain paper.

- CAM-Computer Aided Manufacturing (CAM) is the use of computer control machinery and software to automate a manufacturing process.

- DNC-A Direct Numerical Control (DNC) system operates with a remote central processor controlling several CNC machines via communication lines. The host computer dynamically downloads numerical info “on-the-fly” as CNC machines execute operations.

- CNCDesign-It is utilized to convert the design made by Computer-Aided Design software (CAD), into numerical values.

CNCTrain software has the following features

You can simulate 3D graphics in it.

On-screen MDI: This application enables you to work with multiple documents at the same time.

Multiple Controls.

ISO Programming.

Linear and Circular Interpolation.

Radius Compensation.

User-friendly choice window for G&M codes.

A wizard to guide beginners through programming syntax, tooling windows for tool choice, offsets, etc.

Datum control techniques.

CNCTrain has an inherent instrument panel to inform trainees about the industrial control panel.

You'll be able to add an external MDI control panel hardware to realize the tactile expertise in operating with industrial CNC panels.

Use of CNCTrain software

Use of CNCTrain software

As I already mentioned, CNCTrain is employed to make 2D, 2.5D, or 3D models for carving or cutting, CAM software system is employed to get tool paths and g-codes, CNC control software is employed to send these g-codes and move together with your CNC machine software system simulates the move notice error before you create them in real.

Utilization of CNCTrain in industry

We can also use CNCTrain in industries when we need to remove metal. The machines withdraw excess metal from raw materials to make advanced elements. An example is the automotive industry where we carved automotive parts (gears, shafts and other complex parts) from raw material.Industrial elements need precise engineering and timely turnaround.To adhere to these strict standards, several sectors use computer numerical control (CNC) machines to make the custom elements they need. These industries need authentic, well-made parts with a high level of preciseness.

Applications of CNCTrain

CNCTrain could be a producing process suitable for a wide variety of industries including

Automotive

Aerospace

It is Ready to manufacture a variety of merchandise, like auto mobile frames, surgical instrumentality, aeroplane engines, gear, and hand and garden tools.

Conclusion

As a mechanical engineering background, if you want to start a career in the digital manufacturing technology field. Knowledge of CNCtrain will definitely help you. If you're interested in learning more about CNCTrain, Abhyaz offers a skill development program as well as an internship program where you can obtain more hands-on experience.

FAQs

Q1. What's a CNCTrainer simulator?

Ans. CNC simulation tools are mathematical applications designed to predict the behaviour, performance, and outcome of certain manufacturing processes.

Q2. What is the distinction between CNC and VMC?

Ans.CNC could be a form of the motion control system. It means that instead of using cams or templates to cut a part, it is controlled by a computer. A VMC could be a form of CNC machine, commonly enclosed and most often used for cutting material.

Q3. How do simulate several CNC control types?

Ans. To select the control that you would like to simulate click on the 'Control Type' menu at the top of the screen and choose any of the active listed controls.

Q4. What is CNC software used for?

Ans. CNC software is employed to translate computer-aided design (CAD) to manufacturing work pieces with computer-aided manufacturing (CAM) on your CNC machine.

Q5. Does the Abhyaz platform provide training for digital manufacturing tools?

Ans.Yes, Abhyaz provides training as well as internships to obtain more experience.