An In-Depth Guide to Software Integration and Configuration

INTRODUCTION:

Manufacturing methodologies have been completely transformed in the dynamic field of industrial automation by the combination of advanced robots and smart software solutions. Technology integration is critical, whether it is for designing intricate robotic arms on auto assembly lines or managing the accuracy of arc welding stations. Greetings from a world where imagination meets reality - a world in which RobotStudio is the portal to offline programming and robotic application simulation. We explore the foundations of RobotStudio in this extensive introduction, revealing its potential to influence industrial robots in the future. Furthermore, we discuss software-driven workstation design for robotic welding applications, emphasizing the critical role that software tools play in maximizing accuracy, productivity, and smooth integration.

Join us as we investigate the links between innovation and manufacturing, equipping you to use robotics and software to drive productivity and excellence in welding operations.DESCRIPTION OF ROBOT STUDIO:

The most widely used offline programming and simulation tool for robotic applications worldwide is called RobotStudio. The RobotStudio suite, which is built on the finest virtual controller technology available, gives you complete assurance that the movements you see on your computer correspond to the actual movements of the robot. This innovative technology drastically reduces commissioning time and increases productivity by allowing you to design, test, and fine-tune your robot installation in a virtual setting.

For both professionals and passionate individuals of robotics, RobotStudio is similar to a virtual playground. With the help of this PC application, you can easily simulate whole robot stations, program robots, and create CAD items. RobotStudio is an intuitive interface that enables you to realize your robotic ideas, regardless of your level of experience as an engineer.

GETTING STARTED:

Workstations for robotic welding comprise a wide range of parts, such as robots, controllers, equipment, safety precautions, and CAD models. These components come together to form a seamless setting where welding jobs are completed with the highest accuracy and effectiveness. The coordination of the assembly and configuration of these workstations is greatly aided by software programs like Robot Studio, which allow engineers to create, program, and simulate robotic activities offline. Manufacturers can increase total productivity and profitability by streamlining workstation design, optimizing resource use, and mitigating operational hazards by utilizing advanced software functions

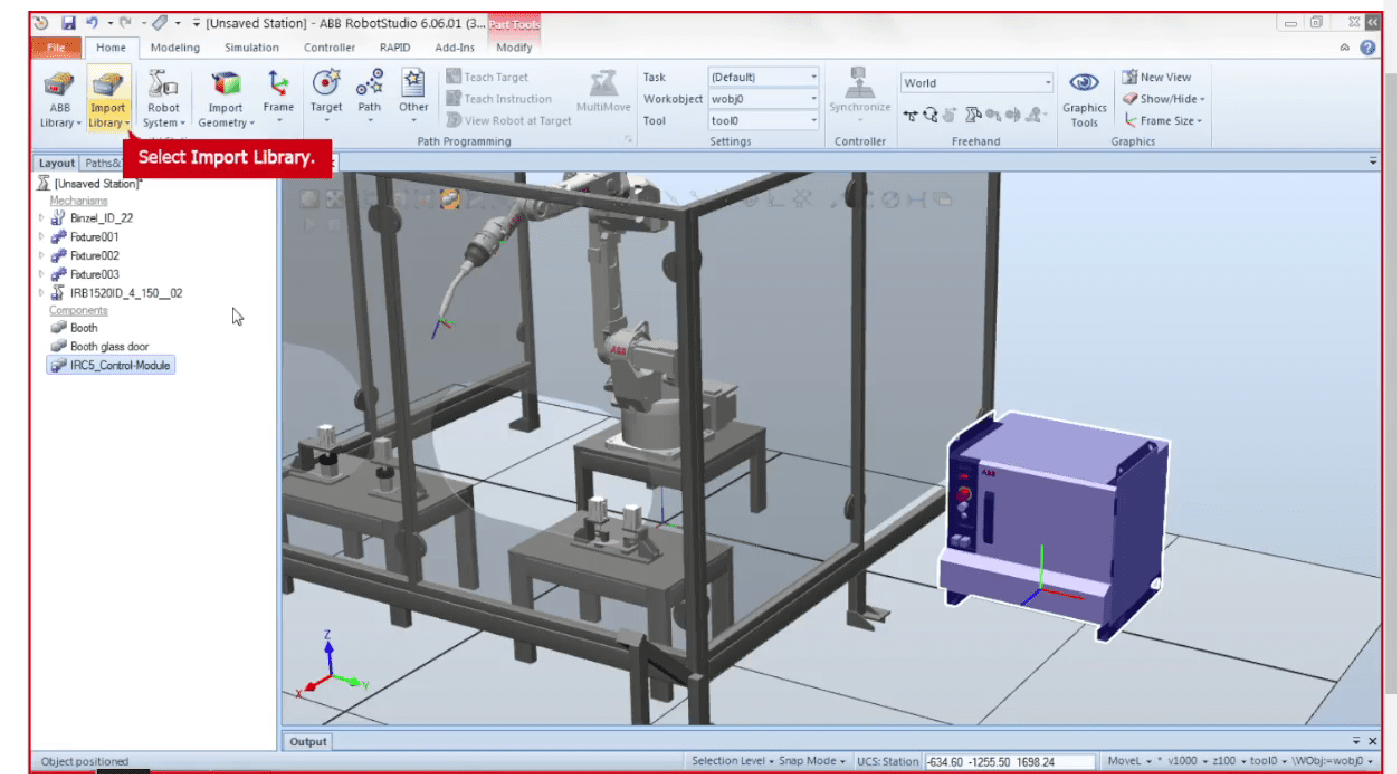

Let's start our exploration of robotics by imagining how to put up a RobotStudio arc-welding robot station. Our priority is to set up a new workstation. Choosing the required parts, such as robots, controllers, tools, and safety measures, is usually included in this.CREATING A NEW WORKSTATION:

With RobotStudio, all it takes is a few clicks to create a new workspace. To begin, Launching Robot Studio and choosing the components you want for the workstation layout are the first steps in building a new workstation. Engineers may load CAD models, position robots and controllers, establish tooling and safety features, and more through a series of simple procedures. The program ensures ergonomic efficiency and spatial coherence by facilitating the smooth integration of many components of a workstation. Additionally, Robot Studio allows the import of CAD data in a variety of file formats, such as IGES, STEP, and STL, which improves workstation design flexibility and interoperability.

IMPORTING CAD OBJECTS:

After choosing your parts, it's time to integrate them into RobotStudio's virtual environment. To do this, CAD files for the booths, fixtures, and safety panels that make up the workstation must be imported. You can see how the actual pieces will fit together in the workstation by looking at the exact representations of the things provided by these CAD files.

COMPONENT ORIENTATION AND POSITIONING:

Robot Studio offers the capabilities necessary to precisely position robots and welding instruments, guarantee smooth workstation operations, maximize welding efficiency, optimize reachability, and reduce collision hazards. so the next step is to position and orient the imported CAD objects within the workstation. This entails giving the orientation in degrees together with the coordinates for X, Y, and Z. You may make sure the workstation works as expected and that the robots can move around the area freely by precisely placing each component.

ATTACHING TOOLS AND ACCESSORIES:

Without the required equipment and accessories, no robot workstation is complete. This might involve attaching welding torches to the robot flange in our arc welding example, in addition to flex pendants for manual control. You can replicate the entire robot station workflow by affixing these tools to the relevant parts. Robot Studio makes it easier to position, integrate, and configure robots in workstation environments, including pendant units and controllers. It offers seamless communication, reduces downtime and streamlines production by allowing engineers to simulate the positions and activities of virtual controllers. It also makes offline programming possible.

TESTING AND SIMULATING:

Now that everything is configured, it's time to test your workstation! With RobotStudio, you can mimic the robots' movements and make sure everything is operating as it should. You can experiment with various scenarios, change the settings, and perfect your arrangement until you're happy with the outcome. It's time to save your workstation design once you're satisfied with the simulation results. You can come back to your work at a later time to make further changes or analyses by saving it. Furthermore, you can export code from RobotStudio to program actual robots, closing the gap between virtual simulation and practical application.

Besides this RobotStudio's capability to support cooperation and decision-making is one of its best characteristics. You may share your workstation designs with others and get real-time feedback whether you're working alone or in a group. By working together, you can guarantee that everyone agrees and expedite the design process.CONCLUSION:

RobotStudio is a crucial tool for mastering robotic welding workstations, enabling manufacturers to streamline setup, optimize component positioning, and improve productivity. Its intuitive interfaces and robust simulation capabilities enable engineers to design, program, and simulate robotic welding operations with precision. As technology evolves, RobotStudio will drive innovation in robotic welding.

We also invite you to visit our website, CNCTrain where you may find a variety of courses aimed at improving your knowledge and abilities in robotics, automation, and CNC machining. To learn how to take advantage of new opportunities in the field of industrial automation. so now click on Simulation Software to learn more about the software we provide for industrial solutions and get in touch with us or you can directly contact us for product enquiry, partner or consultant enquiry and any support enquiry.