Introduction

In a previous blog we discussed why robots are used in industry and we also discussed the anatomy of industrial robots. So let us move ahead. In this blog we will discuss robot system. We also want to know about robot systems about robots.Robotic systems are defined as systems that provide intelligent services and information by interacting with their environment, including human beings, using a variety of sensors, actuators, and human interfaces.

Here, we will discuss robot system.

About Robot System

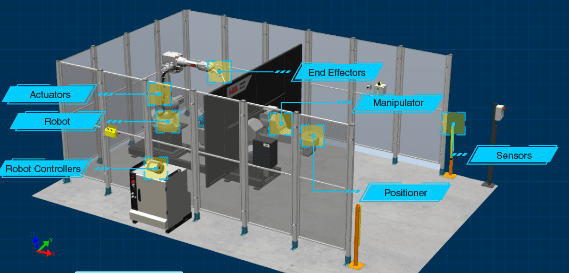

You know robot system includes actuators, robots, robot controllers, end effectors, manipulators, sensors and position-er each one of them performs specific task in robot. Robotics is the study of the design, building, and use of machines (robots) to do jobs that were previously performed by humans. Robots are frequently used in industries such as automobile manufacturing to perform simple repetitive tasks, as well as in organizations where employees must operate in hazardous environments. Robotic systems are employed in a variety of industries, including health care, agriculture, food preparation, industry, and the military, as I discussed in my last blog. So let us discuss robot systems

Robot system

A robot system comprises of:

Actuators

Robot

Robot controllers

End effectors-

Manipulators

Sensors

Position-er

End effectors

End effectors is an object that can be mounted directly or indirectly on the robot turning disk or fitted in a fixed position within the robot's working range. Each end effectors that can be used by the robot must be measured and stored in order to achieve accurate positioning of the tool center points

there are two types of end effectors.

Grippers- To grasp and manipulate objects during operation, such as pick and place, assembly, and machine tending, mechanical, vacuum and adhesive type of grippers are available.

Tools-To perform processes, such are arc and spot welding, painting, de-burring, and polishing, arc welding torch, spot welding gun, spray painting nozzles, grinding wheels are available. All tools must be defined with a TCP.

Robot drive system

The robot's capacity to move its body, arm, and wrist is provided by the drive system or actuator which is used to power the robot. The drive system determines the robot's speed of operation, load carrying capacity, and its dynamic performance. To some extent, the drive system determines the kinds of application also.

commercially available industrial robots powered by one of three types of drive system

Hydraulic drive

Electric drive

Pneumatic drive

Robot transmission system

There are many ways to perform mechanical power transmission. These include belts and pulleys, ball screw, chains and sprockets, gears, transmission shafts, harmonic drives and screws

Sensors

Robot sensors measure robot configuration or condition and its environment and send such information to the robot controller as electronic signals.

There are mainly two types of sensors.

(i) Internal sensors-Internal sensors are responsible for the internal working of the robot and used for closing the loop in feedback control

(ii) External sensors- External sensors are responsible for interaction with the environment. A robot can use external sensors for interaction with the environment. If any of these sensors fail, the robot can still function but its ability to interact with the external sensors world is reduced.

Robot control system

Robot sensors measure robot configuration or condition and its environment and send such information to the robot controller as electronic signals.

The following are the primary functions of a robot controller:

User interface.

Data storage.

Motion planning.

Real-time control of joints motion.

Sensor data acquisition.

Interaction and synchronization with other machine.

Interaction with other computational resources.

Types of robot control system

There are many types of control systems.

(i) Limited sequence control- Pick and place operations using mechanical positions.

(ii) Playback with point-to-point control- Records work cycle as a sequence of points, then plays back the sequence during program execution.

(iii) Playback with continuous path control- Greater memory capacity and Interpolation capability to execute paths in addition to points.

(iv) Intelligent control- Exhibits behavior that makes it appear intelligent.

lets discuss about Robot programming.

Robot Programming

you know Robot programming is a set of instructions or coded commands that tell a mechanical device and electronics system what task to perform and control its actions without human intervention.

Robot programming is the defining of desired motions, also includes interpreting sensors data, actuating the end effectors, sending to the equipment in the cell, receiving data from devices and making computations and decisions.

Types of robot Programming

Different types of robot programming are

(i) Online programming- Online programming uses robots to generate the program. It teaches or guides the robot through a sequences of motions that can be executed repeatedly.

(ii) Offline programming- Offline programming writes a program using a text-based robot programming language.It does not need access to the robot until its final testing and implementation.

(iii) combination programming- Combination programming is a combination of offline and online programming. It uses online programming to teach locations in space, and offline programming to define the task or sequences of the operations.

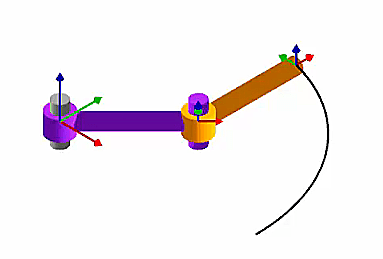

Work Envelope

The workspace also called as work envelope of the robot manipulator is defined as the volume in space that a robot end-effectors can reach. The workspace limits are due to the total reach of the combined robot links. The workspace limits are also due to the specific joints limits of each joint.

Depending on the configuration and size of the links and wrist joints, robots can reach a collection of points called a workspace.

Alternately, workspace perhaps found, by moving each joint through its range of motions and combining all the space it can reach and subtracting what space it cannot reach.

There are three types of work envelop

Maximum envelope

Restricted envelope

Operating envelope

Kinematics

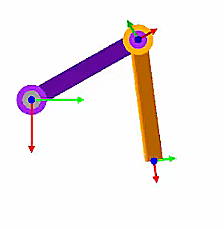

Kinematics studies the motion of bodies without consideration of the forces or moments that produce the motion. Robot Kinematics refers to the analytical study of the motion of a robot manipulator

There are two types of robot kinematics-

Forward Kinematics- Calculating the position and orientation of the end-effectors in terms of joint variable is called forward kinematics. You can find the position of any points(x,y and z coordinates) using forward kinematics.

Inverse Kinematics- Calculating each joint variable, If the end effectors I needed to obtain the position and orientation is called inverse kinematics. You can find the angles of each joint needed to obtain the position using the inverse kinematics.

Conclusion

Every company or industry wants to improve productivity, safety efficiency, customer satisfaction, consistency, perfection etc. That is why they use robot systems in their company or industry.If you want to go in the robotics field. Knowledge of robotics definitely helps you. If you belong to the mechanical and robotics engineering field and you want to start a career in this field. Abhyaz offers a skill development program as well as an internship program where you can obtain more hands-on experience.

FAQs

Q.1 What are robots made of?

Ans. Robot arms are typically made of raw materials like steel, aluminum and cast iron.

Q2. How do robots learn things?

Ans. Roughly speaking, robots can learn new things in three ways: under complete supervision, under no supervision, or somewhere between the two.

Q3. How have robots changed the way we work?

Ans. Robots can improve efficiency and quality, reduce costs, and even help create more jobs for their human counterparts.

Q4. Does the Abhyaz platform provide training for Robotics?

Ans. Yes, Abhyaz provides training as well as internships to obtain more experience.