Hello, learners and skill searchers!

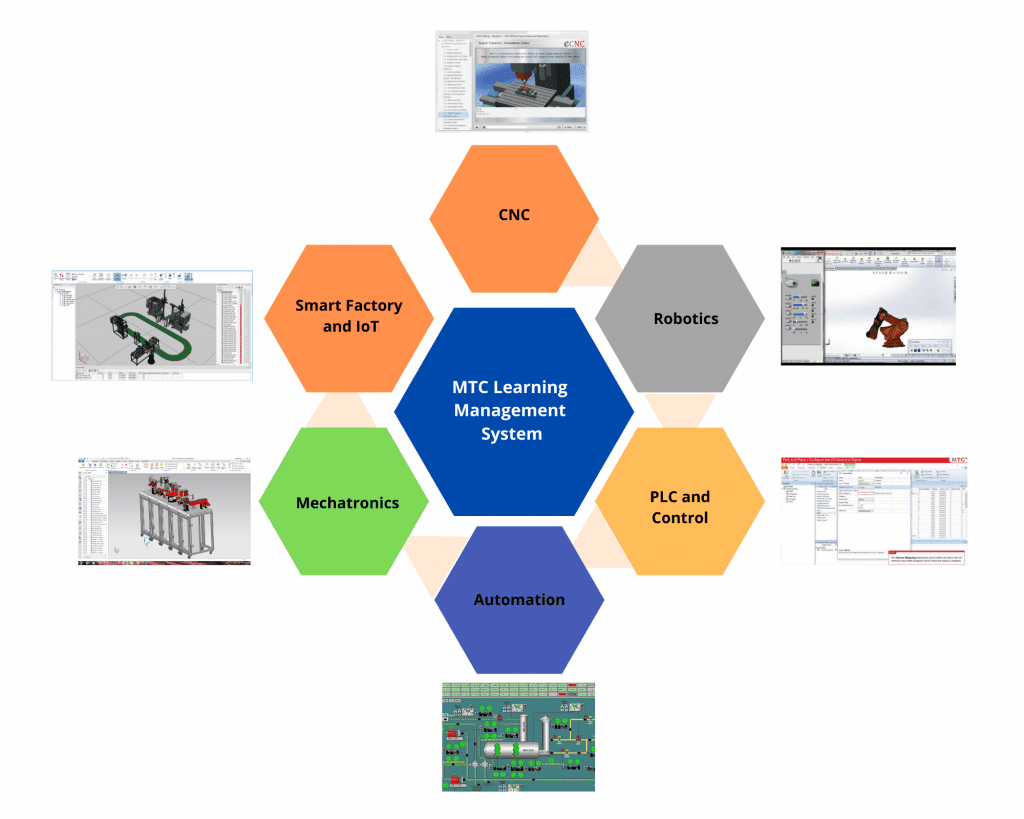

We will talk about the value of online education in digital manufacturing. The mass-production sector is growing with the use of digital manufacturing. High techs like robotics, CNC, automation, and mechatronics, are all becoming popular to increase production profitability.

THE FOLLOWING ARE THE MOST IMPORTANT AND ESSENTIAL FACTORS WHEN IT COMES TO IMPROVING A PERSON'S SKILLS IN THE AREA OF DIGITAL MANUFACTURING.

- E-learning has turned into a great for both companies and employees to stay up to date on the latest skills.

- Everyone interested in the manufacturing process can use modern procedures and styles by upskilling

- E-learning allows companies to keep their staff up to date on rising techniques.

- Helpful in developing a practice of continuous improvement in new the innovations era.

- The continuously growing skill set has made e-learning a valuable tool in the area of digital manufacturing.

- Providing quick, easy access to the latest information, and updated training tools.

- E-learning guarantee that the person remains parallel to the sector's needs.

- E-learning gives assurance that employees remain competitive and gainful in this growing market.

- Companies may make sure that their staff is experienced and able to handle the recent innovations.

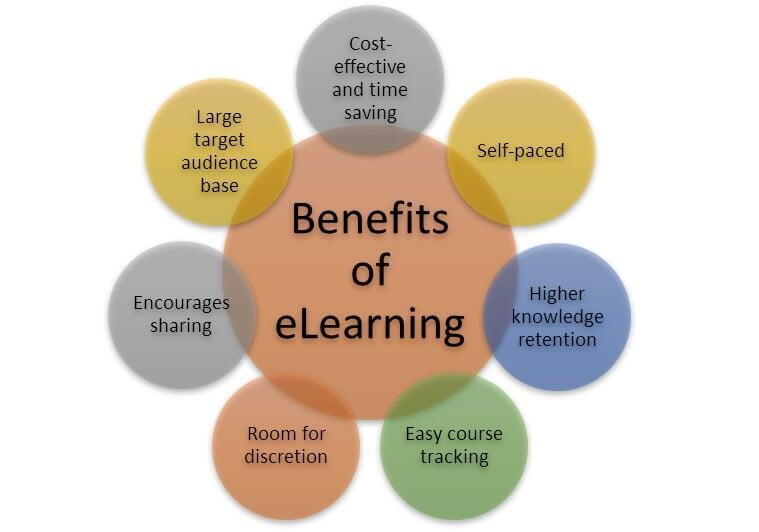

- E-learning provides several benefits over old-style training techniques.

A FEW BENEFITS OF E-LEARNING IN DIGITAL MANUFACTURING

1. STUDY COMFORT

- Employees have the convenience of studying whenever they choose thanks to e-learning.

- Downtime in the industrial sector can be costly, so e-learning is an easy way to stay skilled while saving time.

- Learning materials are available online, so they're easy to manage.

- a productive way to manage the work and learning in an organized manner.

- Businesses may make sure that their employees keep up with new scientific advances.

2. KEEP UP WITH E-LEARNING COURSES

- The demand for new technologies gives rise to e-learning as an easy way to stay skilled.

- to stay up-to-date in digital manufacturing, where innovations are often made.

- access to up-to-date training resources anywhere in the world and stay skilled and confident.

3. SPECIALIZED KNOWLEDGE OF THE WORK

- E-learning helps train employees in a specific area of expertise, which in turn can improve productivity and overall workflow outcomes.

- Employees must be competent to run updated machines and automated manufacturing processes.

- Learn how to operate and program robots and repair computers and machinery the easy way.

- By providing employees with the proper training, companies may increase industrial output.

- Lowering downtime can lead to a loss; the only way out is an experienced workforce.

- The manufacturing industry needs to be modernized, and skilled workers are needed to boost the life of the machine.

4. E-LEARNING IS MUCH CHEAPER

- For a huge number of employees, e-learning is a cheaper method for training.

- Classroom-based training is one of the more time and money-consuming traditional training methods.

- E-learning reduces the need for physical training materials, travel costs, and higher fees.

- Companies can increase the profit and lifespan of the machine through skilled staff.

UNDERSTANDING THE FOLLOWING TERMS WILL HELP YOU LEARN BETTER AND MAKE BETTER DECISIONS

DIGITAL MANUFACTURING: Digital manufacturing is the use of digital technology in design and production to make the entire process effortless. Automation, data analysis, and intelligent decision-making are a few of the systems. It is important for digital manufacturing to adopt new methods, which is a must in a fast-growing time.

- Using this strategy, producers may improve output while cutting costs and operational budgets.

INDUSTRY 4.0: The wording "industry 4.0" is often referred to as the "fourth industrial revolution," which means the adoption of digital technology into the production process. Easy, intelligent decision-making based on real-time data Industry 4.0 aims to build a smart factory that can perform autonomous operations.

A FEW EXAMPLES OF THE TECHNOLOGY’S AS FOLLOWS

- The internet of things (IoT)

- Cloud computing

- Artificial intelligence (AI)

- Machine learning (ML)

AUTOMATION: The use of technology such as robots and machines to perform tasks previously performed by humans is called automation, a new type of method that helps increase efficiency. Save money by reducing the number of errors and the time it takes to complete a task compared to humans. Need updated skill sets and knowledge to automate production processes.Gain the knowledge required to design a program and maintain such automated systems.

MECHATRONICS: The subject of mechatronics uses mechanical, electrical, and computer engineering. These systems could include advanced technology, automated processes, and robots.

- Allows the development of intelligent machines that can make decisions based on real-time data.

ROBOTICS: The field of robotics includes the design and development of robots for various uses. The use of robots in manufacturing has become more common in recent years. Their ability to do repetitive, fast, and precise tasks compared to human potentiality.

- Examples of robotics are common in fields like production, healthcare, and even space research.

- Businesses need to upgrade to the new technology and skills necessary to build robots.

- It is important to create and manage robots for many applications to handle workflows.

CNC: The use of computers to control manufacturing machinery relates to "computer numerical control." Perfect control over the production process is possible with this method. Helpful in efficiency and better-quality goods

WHY IS UPSKILLING IMPORTANT IN DIGITAL MANUFACTURING

- The skills needed by employees in manufacturing have changed as a result of digital technological transformations.

- Manufacturing companies now need to adjust to the developing technologies.

- Traditional manufacturing skills are old-fashioned.

- E-learning content is an essential resource in today's time frame.

- Companies want fresh talent through online training since digital manufacturing is a constantly evolving industry.

- Skilled staff is crucial for the industrial sector since downtime may be expensive.

Take your skills to the next level by starting to explore the world of e-learning!

WHAT IS DIGITAL MANUFACTURING?

- Digital manufacturing uses digital technology to make designing and producing things easier, with systems like automation and data analysis. It helps improve output and save money.

2. WHY IS E-LEARNING IMPORTANT IN DIGITAL MANUFACTURING?

- E-learning is important in digital manufacturing to improve skills and knowledge in a flexible, accessible, and cost-effective way.

3. WHAT IS INDUSTRY 4.0?

- Industry 4.0 means using digital technology in production. IoT, cloud, AI, and machine learning make smart decisions using data.

4. WHAT IS AUTOMATION?

- Automation is using robots and machines to do jobs instead of people. It makes work faster, cheaper, and less wrong. Learn how to use it to improve manufacturing.

5. WHAT IS MECHATRONICS?

- The subject of mechatronics uses mechanical, electrical, and computer engineering. allows the development of intelligent machines that can make decisions based on real-time data.

6. WHAT IS ROBOTICS?

- Robotics designs robots for different uses, like in factories and healthcare. They do fast, precise work. Learn how to build and use robots.

7. WHAT IS CNC?

- Computers control manufacturing machines using "computer numerical control." This helps make production efficient and improve quality.

8. WHY IS E-LEARNING AN EASY WAY TO UPSKILL?

- E-learning offers accessible and flexible training at your own speed of learning, with interactive materials and assessments..

9. WHY DOES E-LEARNING SAVE TIME WHILE WORKING AND LEARNING?

- E-learning allows people to learn at their own pace and on their own schedule without having to travel to a specific location.